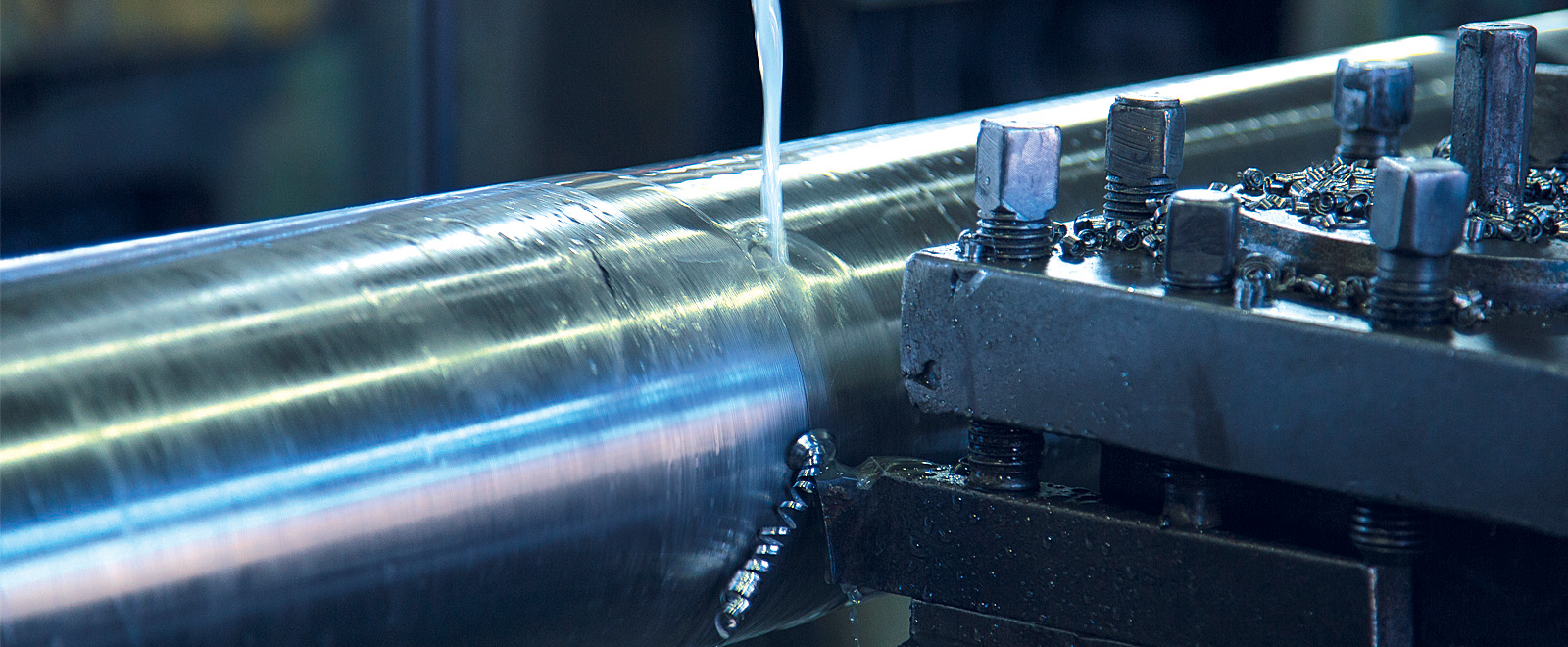

About "Dnepropress Steel" LLC

“Dnepropress Steel” Co.Ltd - a promising young company, established on the basis of “ Dnepropress” factory, which was founded in 1955 in the city of Dnepropetrovsk, Ukraine. “Dnepropress Steel” Co.Ltd brings together a team of highly skilled professionals focused on providing a full range of services regarding the production of forgings. “Dnepropress Steel” Co.Ltd has a closed cycle of production of forgings - from ingot melting to machining - and established itself as a reliable and responsible supplier with an individual approach to each customer. The production of “Dnepropress Steel” Co.Ltd is consumed by the world-famous companies and used in the energy, petrochemical, nuclear power, shipbuilding, metallurgy, machinebuilding industry and the general importance industries. The main purpose of “Dnepropress Steel” Co.Ltd is to preserve the interests of partners and awless execution of commitments.

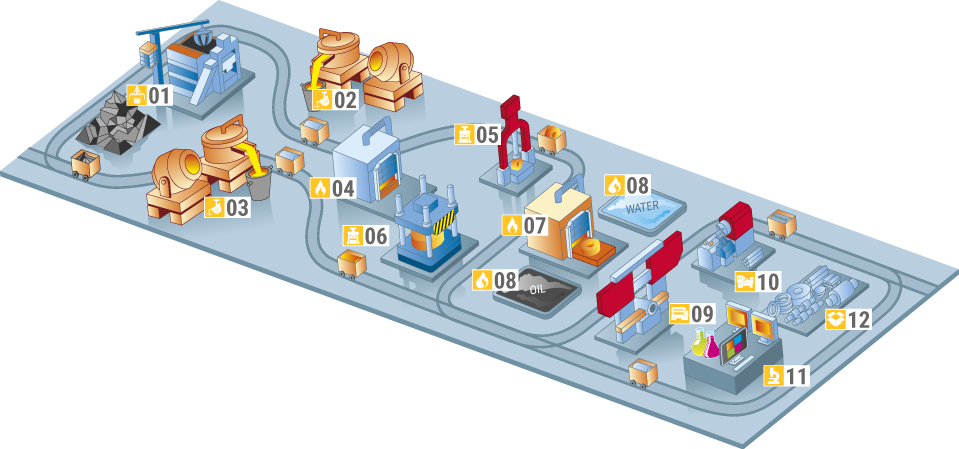

PRODUCTION STAGES

Dnepropress Steel Plant has a full production cycle from smelting to finished products, which includes: steelmaking, forging and pressing, all types of heat treatment, mechanical processing.

Production Structure

The production process consists of 12 stages.

Drop-hammer plant

- Capacity 2000 T

- Inotial check? chemical analysis, radiation mmeasuring anlysis, spetrum examination X-ray fluorescence analysis

Steel casting complex 3 Т

- Induction steelmaking furnace 1,8 Т

- nduction steelmaking furnace 1,2 Т

- Gas-oxygeene refining converter 3 Т

- Ignos from 1 Т up to 3 Т

Steel casting complex 15 Т

- Electric arcsteelmaking furnace DC 15 T

- Gas-oxygeene refining converter 15 T

- Ignots up to 15 Т

The heating furnaces

-

- Capasity: 40-80 Т

- Accuracy: ±2°С

- Heatind schedules archiving

- Automatic operation mode

Hammer area

- Hammer 1000 kg

- Hammer 2000 kg

Press area

- Forging complex 1250 ТF

- Press 1250 ТF

- Manupulator 5 T

- Forging comples 2000 ТF

- Press 2000 ТF

- Manipulator 10 Т

- Forgong complex 35000 ТF

- Press 3500 ТF

- Manipulator 20 Т</li

Heat treating furnace

- Capacity: 14-40 Т

- Temperature range: 0-12500°С

- Heatind schedules archiving

- Size: 3200×11500 мм

Heat treatment

- Annealing: L 8000 мм, Ø 3000 мм

- Hardening (oilwater): L 5000 мм, Ø 2700 мм

- Normalization: L 8000 мм, Ø 3000 мм

Cutting

- Belt-saw machines Behringer

- Working window: 1100×1100, 560X560 мм

Мachining

- Milling group: 4000X12000 мм

- Turning lathes group: Ø 1300X1200 мм

- Boring machines with work desk: 16000X5000X3000 мм

- Caroussel group: Ø 3200 мм

Laboratory

- Chemical analysis, ultrasonic testing;

- Surface quality;

- Spectrum estimation;

- Micro macro metal research;

- Mechanical chrasteristiks:

- -yield point;

- -resistance to rupture;

- -hardness;

- -testing from -60 up to 400 °С

Delivery of finished products

- Marking

- Preservation

- Certification

- Packaging